Snow-jet cleaning with quattroClean®

The advanced, patented C02 snow-jet nozzle technology from acp systems AG cleans component surfaces using a dry, environmentally neutral, residue free process.

The advanced, patented C02 snow-jet nozzle technology from acp systems AG cleans component surfaces using a dry, environmentally neutral, residue free process.

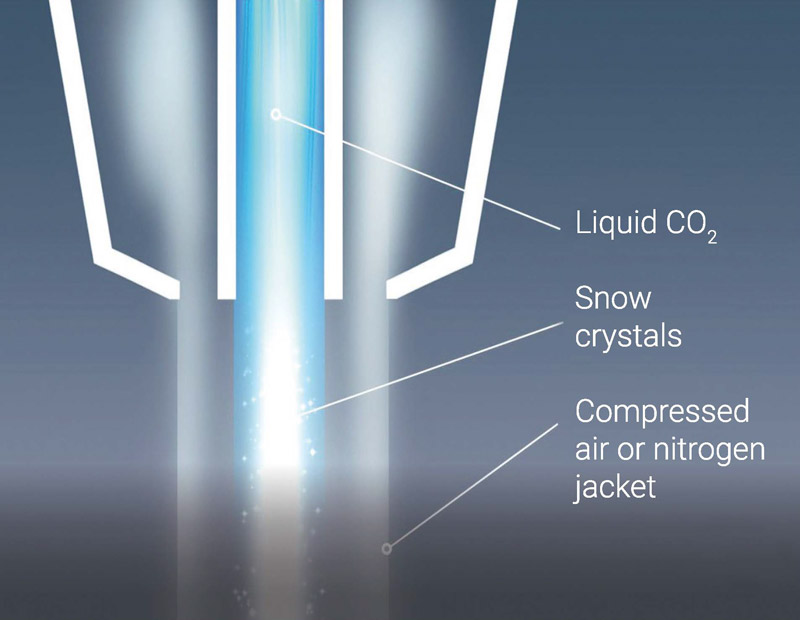

Two-component concentric nozzle

acp systems AG’s advanced and patented dual media nozzle technology is unique and has signiflcant advantages over alternative systems.

The quattroClean® cleaning process comprises four stages: impulse transmission, rapid cooling, sublimation and solvent rinsing.

For inline dry component cleaning applications we developed the new powersnow quattroClean technology. In this innovative process, recycled liquid carbon dioxide is compressed into cleaning granules by a unit integrated into the system. These are then accelerated by compressed air, fed through a nozzle designed especially for the respective purpose and blasted onto the surface to be cleaned. Thanks to the elimination of the customary external pellet production and logistical effort associated with conventional dry ice cleaning, a fully-automated and uninterrupted cleaning or deburring process can be realized.

With the scalable quattroClean snow-jet technology we offer cleanroom-compatible solutions for high-purity cleaning applications. Cleaning is carried out dry with liquid, climate-neutral CO2. Regarding particles, the surface cleanliness class (SCC) 1 is achieved, and SCC 0.1 for parts that have already been wet-chemically fine cleaned. With regard to film-like residual contaminations, the cleaning results are comparable to other ultra-fine cleaning processes such as wet-chemical and plasma cleaning or vacuum bake-out.

C02 snow-jet cleaning can offer up to a 40% cost reduction over conventional cleaning processes in some industry sectors.

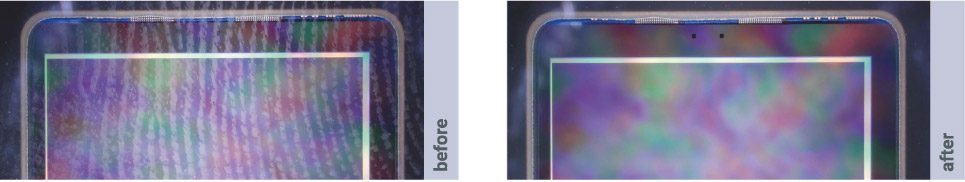

Automotive: CMOS imager

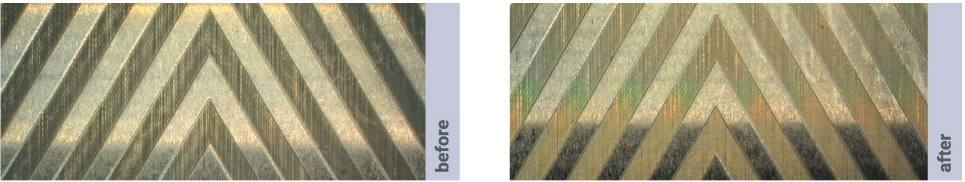

Medical Technology: Degreasing of precision metal components

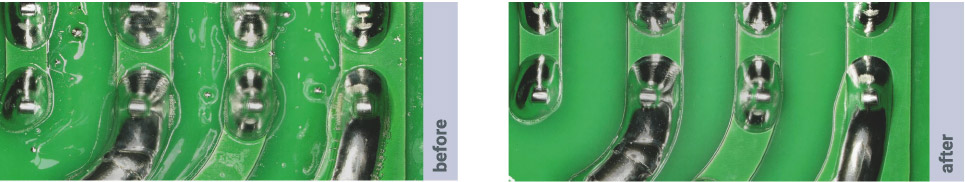

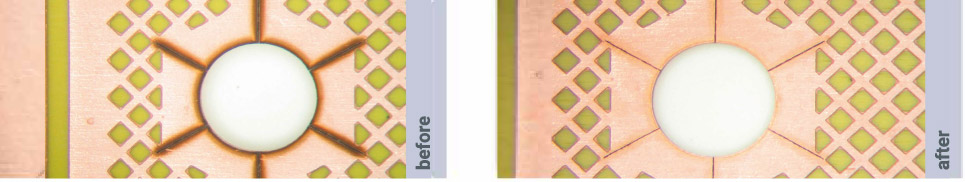

Electronics: PCB – removal of solder and flux residues

Electronics: PCB laser structuring – removal of soot

quattroClean® – Our main products

JetCell®

Flexible, automated production for CO2 snow-jet cleaning; inline, stand-alone and application

JetStation®

Manual or semi-automated enclosed systems for lower volume, specialised or R&D applications