Dispensing is another core competence of acp systems AG. In the following case study, the application of micro-dispensing is used in the photovoltaic industry when applying conductive silver adhesives, precisely to a glass substrate in solar modules. This creates a contact by establishing a connection to the copper track/busbar. This poses two challenges: firstly, the substrate must adhere evenly so that the adhesive can bond to the substrate; and secondly, the adhesive must be applied in an even line or quantity (stable process at 200 µm).

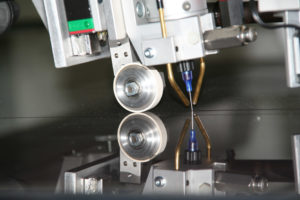

For this purpose, acp has developed a special micro-dosing valve that enables precise dosing of solder pastes, viscous sealants and other materials enriched with solids. The three criteria of time, pressure and dosing quantity are taken into account to ensure a constant quality of adhesive line thickness and metal particles. A constant material flow is maintained by the compressed air and the rotation of the spindle. The quantity is influenced by the dosing time and the diameter of the needle/capillary, the fine adjustment of the quantity can be varied by the motor speed.

Get in touch

Get in touch