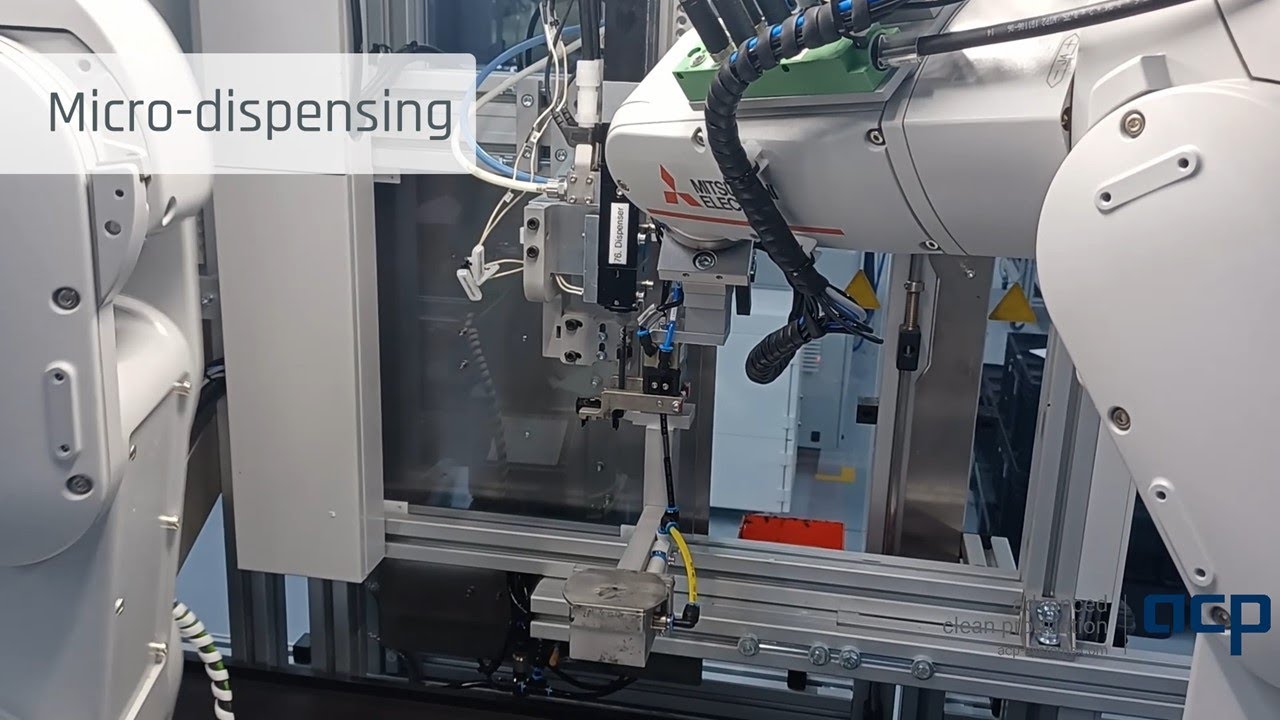

Micro-dispensing

Application specific dosing of pastes and adhesives

Accurate, repeatable and uniform

A core competence of acp systems is high precision micro dispensing. With this technology we support application-specific dosing of pastes and adhesives in an accurate, repeatable and uniform way. Three dimensions are critical. Precision, pressure and dosing quantity need to be exact to guarantee an accurate and repeatable line thickness.

The micro-dispensing valve is a precision valve that has been specifically developed for dispensing solder pastes, viscous sealants and other materials enriched with solids. By combining the principle of spindle conveyance with precise control of time, pressure and dosing quantity, the valve is able to dose exact, repeatable quantities without damaging the metal particles, e.g. the electrical conductive adhesive.

learn more

learn more